if this is to be fixed, we all should understand the history of "plunge cut" rules, who proposed them, and who lobbied for them (and what arguments were used). I'll start with results of a quick search of this very board (and what appears to be its predecessor). I am sure there are many here who can add more factual history...

2010:

http://forum.specmia...46;t=000109;p=0

Jim Drago

"The rules were written to clearly define what can and can not be done in the engine. The goal was to spec a good head, not an unobtainable head, but a good one. There are specs, weights, parts numbers on almost every internal engine piece. The head work is spelled out with dimensions on any and everything that matters. I really see no "gray" areas left for pro engine builders to gain an advantage other than with exceptional machine work and attention to detail in the assembly. Do not underestimate that as it is still a very important, if not the most important part of the process."

Jim Drago

"In my opinion, pro builders who were pushing the envelope on what they were doing before these rules will lose some HP for sure and local guys who were building engines themselves using local NAPA should pick up a little HP by building their engine to the specs with good machine work and assembly. This rule set should definitely tighten the gap between the 'haves" and the "have nots" not grow it"

Bob Thornton

http://www.raceengineering.org:

"The new rules will clarify some commonly asked questions and allow those who choose to build their own engines to do so. Like Jim said "The professional engine builder will have an advantage, but it is a lesser advantage which is much better for the class as a whole."

Like many others I have been concerned about the health of the class and as I make my living from Spec Miata it clearly is advantageous, where I am concerned, for the class to be as healthy as possible.

"

2013:

http://mazdaracers.c...ack-sm-changes/

Dan Tiley Mechanical Engineer,Ti-Speed, Inc.:

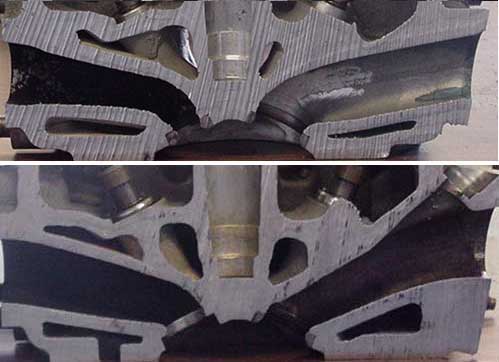

"No really, I'll take (part) of the "blame" for this rule change. I measure the FACTORY plunge cut depth of every port in every cylinder head I build. Out of 12 heads, I had 4 heads that had at least one port that was cut from the factory greater than 9mm before I had even started cutting! I even had a couple outliers that were as high as 14mm. In the SMAC committee we decided that it made sense to open the 1.8L plunge cut depths to the same value as the 1.6L due to the high probability of someone being falsely found non-compliant for running factory equipment. "

Jim Drago East Street Auto Parts :

"This change was made to include so many of the heads that were non compliant from Mazda. The change replicates the existing rule in the 1.6 heads.

I have many calls about " do I need to send my head back to be updated" ABSOLUTELY NOT! There is no gain going down the 12mm, if anything it is detrimental as it slows the air charge. However it does make many of the heads usable that were not before. Also, the heads are no longer available new, so we only have what is out there right now."

Sign In

Sign In Create Account

Create Account

Back to top

Back to top Report

Report