Random thoughts...

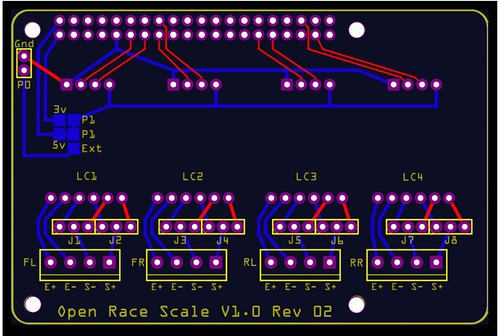

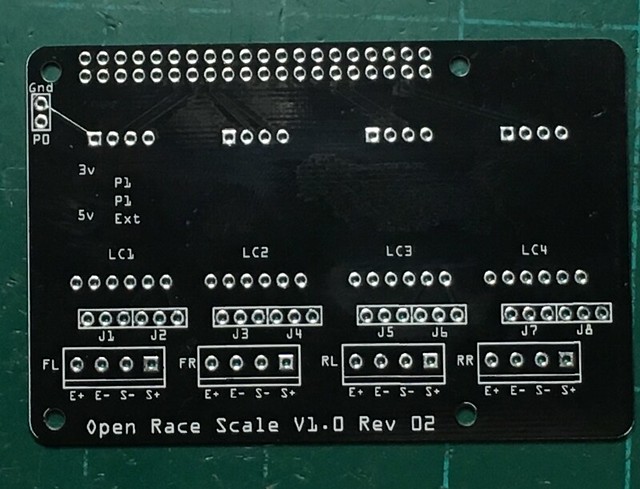

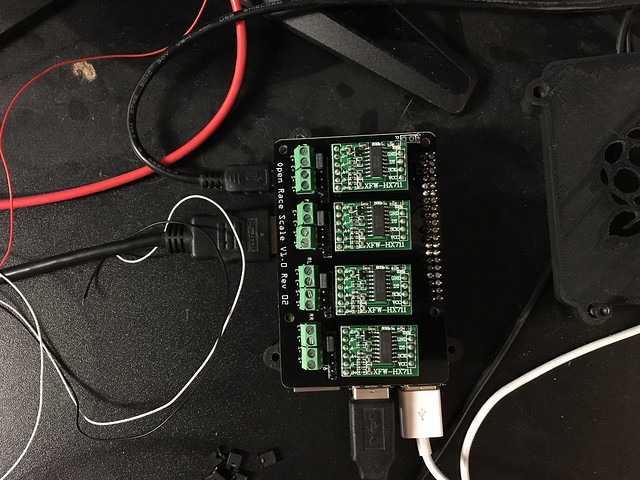

Hardware and PCB fab is my strong point. I know just enough Python to break Andrew's code. ![]()

The HX711 is an amplifier. It takes low level signals from the sensor and amplifies them so the controller has enough voltage to read the input so any like amp will work. The calibration should take take this into account. What matters is a solid voltage delivered to the controller that can then be read by the controller and use that value as a variable in the software.

The sensors can be added in parallel so in this config using multiple sensors will appear to the controller as a single load. That's how your bathroom scale works.

To account for the differences in load cells and pad design it will need some sort of weight based constant calibration routine. In a mass produced scale with a consistent design and supply chain your variables and constants in the parts are know. Those can be programmed into the design and used with minimal input from the user. This is largely due to using a consistent load cell with known values. For example you know 0 volts from the cell is 0lbs but you don't necessarily know how a particular sensor outputs at a given weight. Guys like Longacre use the same cells in a production run of a specific model so they know that at 100 lbs (or whatever the weight is) the voltage from the sensor is X volts. They then use that value as a basis for calculation.

How this sort of project competes on cost isn't being built as a one off. Following the open hardware model vendors buy in bulk and provide kits the end users assemble. That's what we've been doing with 3D printers and desktop/small format CNC for a while. The kit integrators package instructions, source code, files, etc so that you can either buy a kit or make one yourself. That's how open hardware works. As a kit integrator you are selling quality parts, assembly support in terms of documentation and moral support. At this point we've sold parts and full kits for more than 10k machines. Here's an example of the kind of assembly docs a kit integrator may provide. http://roaddoglabs.i...addog_Labs_Bart I'm not into this project to make kits necessarily it's because I think the hardware is cool and others could benefit regardless of anyone selling kits. In some more vertical market projects group buys can take the place of kit integrators.

In terms of competition driving price points that's what happened not only with printers but with routers, low power laser cutter/engravers and mechanised plasma cutting. Printers that 7-8 years ago that were $10k lost out to machines that cost a fraction of that once the patents expired and the Reprap movement started pumping out open designs. It's to the point now where cheap imports have flooded the market and displaced most kit integrators. In fact we've stopped building full kits and now mostly sell parts and frames for the cheap import kits. The race scale market is much more narrow than the desktop/hobby CNC market so the units aren't likely there but the desire is.

It won't drive costs down so much on the low end as it will in the mid and high end. Things like multi cell pads, wireless systems, integration to setup software will scale down in costs much more than an entry level scale kit. It should be to the point where you could upgrade your current system using your existing pads with the Open Race Scales controller and software systems.

Sign In

Sign In Create Account

Create Account

Back to top

Back to top Report

Report