After:

Added 1/8" NPT bung for an oil temp sender. It was a pita trying to weld the aluminum bung to the cast aluminum oil pan. Finished it off with some JB Weld just in case...

I tried removing these panels covering the underside of the cavities under the valve cover but bent them up a fair amount trying to pry them out. The previous owner's mechanic had sealed them up with RTV...  Decided to use the valve cover off the '91's motor instead. I might try to fix the old valve cover at a future date. For now, I got better things to spend time on.

Decided to use the valve cover off the '91's motor instead. I might try to fix the old valve cover at a future date. For now, I got better things to spend time on.

Speaking of better things to spend time on.... Started assembling the block today. First time ever doing this and first time using Plastigage too. Interesting experience.

The ACL bearings look a lot different from stock bearings. The stock bearings are rather shiny. The ACLs are... well... not shiny.

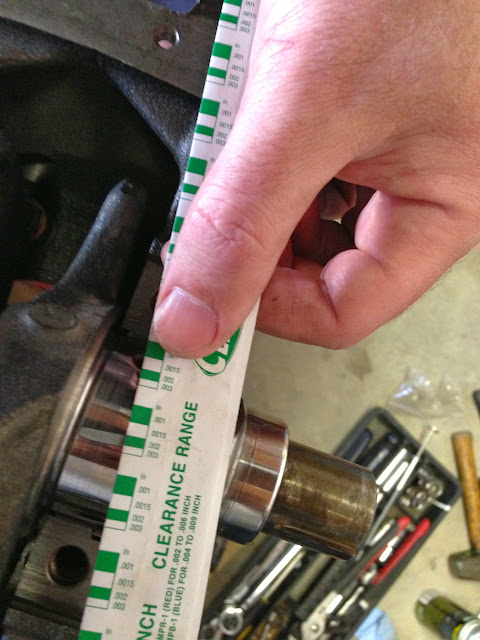

Plastigaging the main bearings. Very consistent. A wee bit bigger than .002 and a bit smaller than .0015.

The crank is now installed and the mains torqued down.

Going to assemble the piston rings tomorrow and install. Real slow going since it's the first time I've ever done this but it's going together nicely. The FSM is not always helpful by itself. Neither is the enthusiast manual. Using those two plus this forum and Googling for answers sometimes yields results - except with regards to piston ring end gaps.

Question:

Do those ACL bearings look normal to you more experienced peeps?

Where can I find specs on the piston ring end gaps? It's not in the FSM for the 1990.

Thanks.

![]()

Sign In

Sign In Create Account

Create Account

Back to top

Back to top Report

Report